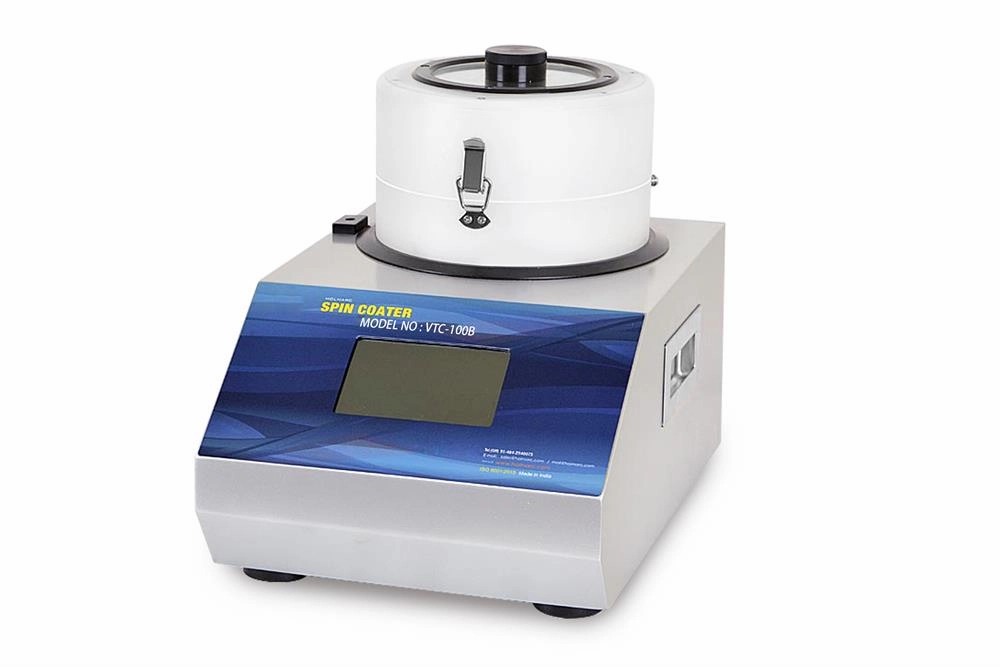

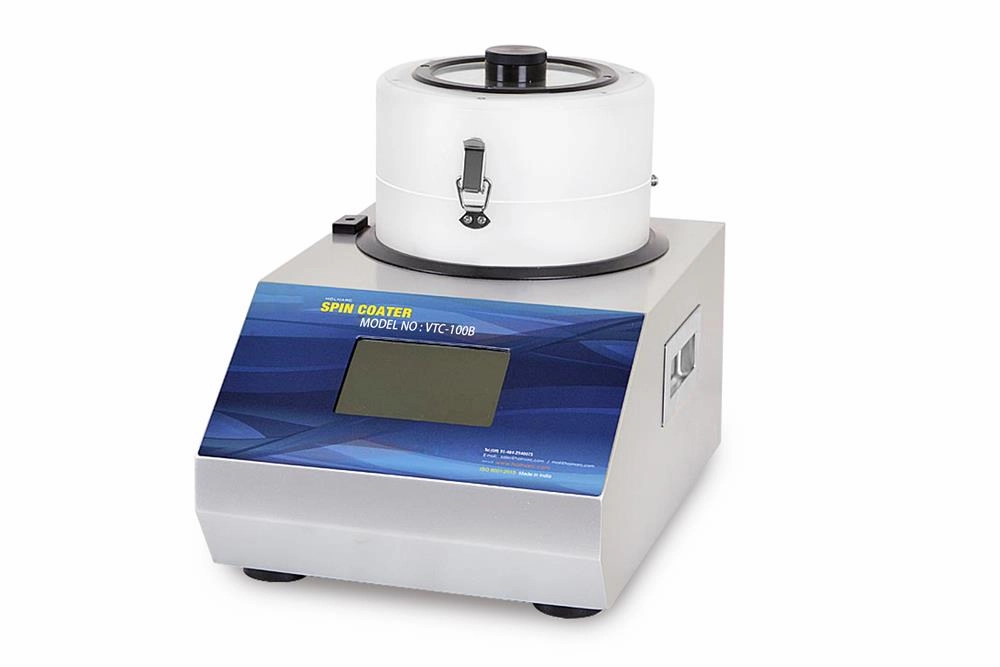

Structure

| - Nylon chamber for anti-corrosive operation.

- One gas inlet port on top of the cover can fill inert gas or pull the vacuum during the coating

- One oil-less vacuum pump is integrated into the spin coater.

|

| Input Power | - AC 110V or 220V, 50Hz, single phase

- Please select the voltage on the options bar

|

Vacuum Chuck & Vacuum pump

| - Nylon anti-corrosive vacuum chucks for holding substrate up to 70mm diameter.

- 3 Vacuum chucks are provided, O-ring sizes OD: 14mm, 22mm and 35mm.

- Substrate Diameter: 30 - 70mm

- Vacuum port size: 8mm

|

| Touchscreen Control Panel | - 60 ~ 9999 rpm spinning speed programmable

- Duration up to 99hours

- Acceleration: 5 - 2000 rpm/sec

- Accuracy: < 5%

- Maximum no of steps: 10

- Can store up to 9 programs

|

| UV Curing Cover | - 365 nm

- UV lights are installed on the top of the cover.

|

Liquid Injecting

| - Standard Package:: 20ml plastic syringe with needle

- Option 1: Precision Electronic Single Channel Pipette: 20 - 200uL

- Option 2: Heatable glass syringe with temp. controller, up to 200C

- Injection Port size: 30mm

|

Gas Inlet

| - A 6mm diameter gas inlet port allows customers to fill desired gasses into the chamber, which can make coating under variable gas flow environment.

|

| Product Dimensions | 400 x 275 x 331 mm (L x W x H) |

| Weight | 34 kg (75 lbs) |

| Compliance | - CE Certified

- NRTL certification is available upon request at extra cost ( Please notice us before ordering if you need NRTL )

|

| Warranty | - One year limited with lifetime support

- Rusting and damage due to improper storage condition or maintenance are not covered by warranty

|

| Operation Manual & Video | |

| Warnings | - Do not overflush the water bowl/base with any kind of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use a fabric cloth to wipe out the residues that remain in the bow/base.

- If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation.

- For more details about the cleaning procedure, please review the cleaning instruction for the spin coaters.

|